-

Phone China market:+86-572-8487027 | +86-572-8487432 Overseas markets:+86-572-8487023Email:

-

TMB Product PortfolioPhone China market:+86-572-8487027 | +86-572-8487432 Overseas markets:+86-572-8487023Email:

-

Phone China market:+86-572-8487027 | +86-572-8487432 Overseas markets:+86-572-8487023Email:

-

Engineered ApplicationsPhone China market:+86-572-8487027 | +86-572-8487432 Overseas markets:+86-572-8487023Email:

-

Connect with TMBPhone China market:+86-572-8487027 | +86-572-8487432 Overseas markets:+86-572-8487023Email:

News Center

Get the latest news and global dynamics instantly!

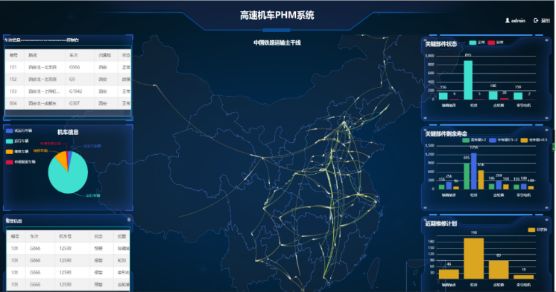

Tianma Bearings leads the way in overcoming high-end bearing condition monitoring and health management technology aimed at big data.

2024-06-07

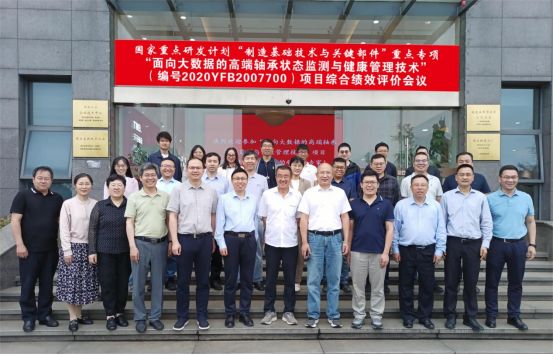

On June 6, 2024, the Industrial and Information Technology Ministry's Industrial Development Promotion Center held a comprehensive performance evaluation meeting for the national key R&D program "Basic Manufacturing Technology and Key Components" project "High-end Bearing Condition Monitoring and Health Management Technology for Big Data" led by Zhejiang Tianma Bearing Group Co., Ltd. The expert group concluded that the project completed the tasks and assessment indicators specified in the task book and achieved the expected goals.

In order to rapidly enhance the intelligent operation and maintenance level of major equipment in China, in November 2020, the project "High-end Bearing Condition Monitoring and Health Management Technology for Big Data" led by Zhejiang Tianma Bearing Group Co., Ltd. was included in the national key R&D program "Basic Manufacturing Technology and Key Components". The project leader is Professor Cao Hongrui from Xi'an Jiaotong University, with other participating units including Shijiazhuang Railway University, Huazhong University of Science and Technology, Shanghai Jiao Tong University, Xi'an Jiaotong University, Tsinghua University, Shanghai University of Applied Technology, as well as CRRC Tangshan Locomotive and Rolling Stock Co., Ltd., Shandong CRRC Wind Power Co., Ltd., and Zhejiang Heqing Flexible Electronics Technology Co., Ltd.

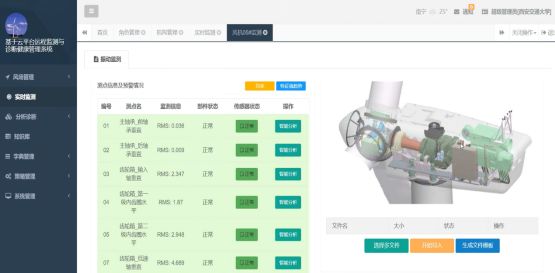

Over the past three years, the research team has focused on the low accuracy of fault diagnosis and the difficulty of predictive maintenance for bearings in major equipment such as wind power and high-speed trains. They conducted research around the scientific problem of intelligent analysis and diagnostic prediction mechanisms for bearing fault information under big data, breaking through five key technologies: high-quality and complete acquisition of multi-source heterogeneous big data for bearing monitoring, construction of health monitoring indicators and dynamic monitoring under varying working conditions, deep transfer intelligent diagnosis of various faults under big data, digital twin-driven bearing performance evaluation and life prediction, and cloud-edge collaborative development of remote monitoring and health management systems. The project has achieved its task objectives and all assessment indicators. It integrated theoretical methods and key technologies to develop a high-end bearing condition monitoring and health management system, which has been validated in five enterprises in the wind power and rail transit industries, promoting a shift from "periodic maintenance" to "predictive maintenance" in these sectors. The important results, innovations, application prospects, and demonstration promotion of the project are as follows:

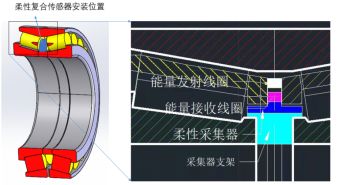

1. Breakthroughs were made in the preparation technology of flexible composite sensors, and bearing samples integrated with flexible composite sensors were developed, achieving embedded perception of signals such as vibration, temperature, and strain, solving problems such as limited installation space for bearings in wind power and high-speed trains, making it difficult to install sensors at close range.

2. A method for constructing monitoring indicators for bearings under varying working conditions and adaptive adjustment was proposed, and a prototype for multi-source signal acquisition and monitoring indicator edge computing was developed, achieving high-speed acquisition of multi-source signals and rapid calculation of condition indicators for bearings. It features functions such as time-domain statistics, frequency-domain statistics, time-frequency domain indicators, time-domain synchronous average indicators, residual signal indicators, and differential signal indicators, with high technological maturity, meeting engineering needs, and has been applied in enterprises such as Baoji CRRC Times Engineering Machinery Co., Ltd.

3. A method for intelligent diagnosis of multiple faults in bearings and remaining life prediction was proposed, and a high-end bearing condition remote monitoring and health management system based on a big data cloud platform was developed, achieving intelligent diagnosis of typical faults and remaining life prediction of bearings under complex service conditions. The research results have been validated in related enterprises in the wind power and rail transit industries.

According to actual measurements, the technical results of this project can achieve a false negative rate and false positive rate of no more than 10% for early fault monitoring of bearings under complex and variable working conditions, a typical fault diagnosis rate of over 95%, and a relative error of remaining life prediction of less than 15%. Multiple indicators have reached the advanced level in the international similar technology field, which helps to rapidly enhance the intelligent operation and maintenance level of major equipment in China.

Related Information

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

Copyright©2024 Zhejiang Tianma Bearing Group Co., Ltd. | Powered by www.300.cn